Waste as raw material – Recycling instead of disposing

Plastics make everyday life better and are necessary for creating a sustainable future. They make vehicles safer and considerably lighter, which conserves batteries in electric vehicles. They efficiently insulate buildings from the heat and cold to reduce the amount of energy required for heating and cooling to a minimum. These are just two of many examples that demonstrate why we need plastic, now and in the future.

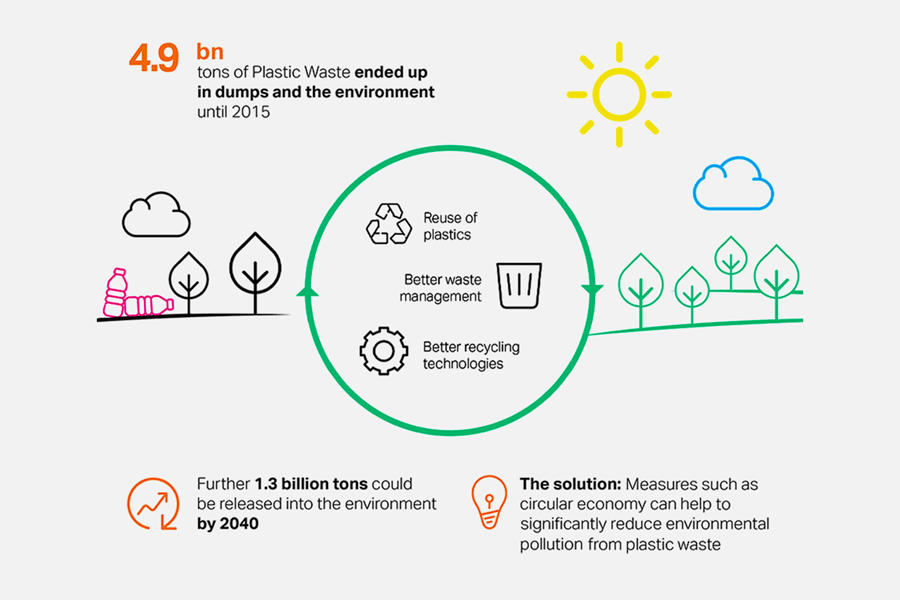

But despite all this, there is also a downside with regard to the way we handle the material when it is no longer needed. The waste that we do not properly dispose of and recycle is a global environmental challenge. From 1950 to 2015, around four-fifths of the world’s plastic waste ended up in landfills and in the environment.

Valuable resource

The vast majority of all plastics are thrown away after they are produced and used. Used plastic is a valuable raw material source. Therefore, it is all the more important to systematically and efficiently recycle plastic waste. This still happens too rarely. According to the OECD, only about nine percent of all plastic waste is actually recycled worldwide.

A key problem is that the necessary infrastructure is missing. According to the United Nations, around two billion people – one quarter of the world’s population – have no access to regular, industrial-level waste disposal or collection systems. This is where we need to take action – quickly and decisively. It is imperative that we build and expand effective waste management systems, develop products that are optimally designed for a Circular Economy and inform consumers about sustainable consumer behavior.

Circular Economy as a key

A Circular Economy that relies on state-of-the-art technologies is the solution of the future. By embracing a Circular Economy as a guiding principle, we could significantly reduce the amount of plastic waste that is released into the environment each year. Covestro is intensifying its research into recycling methods and is open to new technologies, supporting innovative approaches such as chemical recycling.

Promote recycling with partners

Together with partners in China, Covestro has already developed an innovative recycling concept for reusing important raw materials. With this concept, used water bottles made of the high-performance plastic polycarbonate are broken down into their material components for reuse. Covestro then uses the recycled components to produce new plastic granulate for electronic products such as laptops, printers and copiers.