Our Mass Balance Approach – transparent and credible

Plastics are needed for a climate-neutral world. However, they can do better because most of them are still made from fossil raw materials, which contribute to greenhouse gas emissions. This is why fossils need to be ultimately replaced by all viable alternative feedstocks, be it bio-based or recycled. A method helps the plastics industry to get there faster: the mass balance approach.

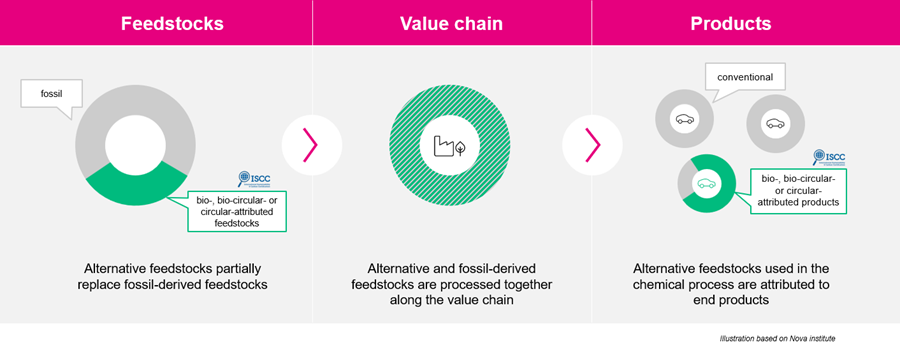

Future-oriented chain of custody model

The mass balance approach is a chain of custody model used to process both alternative and fossil feedstock together. In the end the proportion of alternative building blocks can be properly assigned to the end products on a bookkeeping basis.

The mass balance approach supports compliance with environmental objectives and requirements. The background is that governments and industry bodies increasingly set targets and standards for recycled and renewable content shares in products to improve their carbon footprint and propel the plastic circularity.

The method is considered as a verifiable and transparent concept that is globally applied and supported by large business associations such as Cefic and Plastics Europe in Europe or ACC in the USA. And with ISCC PLUS there is a globally recognized sustainability certification system in place, especially designed for the bioeconomy and circular economy.

Covestro embraces the mass balance approach

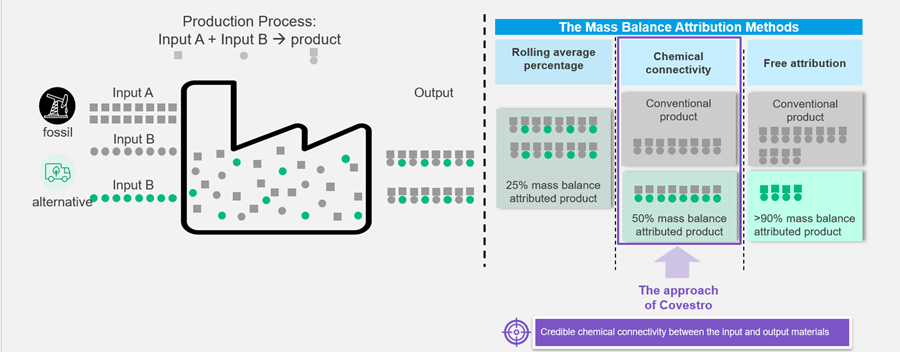

Covestro as a trailblazer fully embraces this future-oriented approach. By applying ISCC PLUS certification, the company provides a clear and verifiable method for the use and attribution of alternative materials to its products. This enhances credibility and trust in sustainability claims of Covestro. Such transparency is crucial for consumers, industry and other stakeholders who demand accountability and verified information in environmental practices.

Covestro is also committed to aligning the mass balance methodology with real chemical processes. This approach ensures that claims about sustainable content are credible and verifiable, while also fostering scalability and compliance with upcoming regulatory frameworks. For more details see the Covestro Mass Balance Position Paper.

Numerous benefits for customers

The mass balance solutions of Covestro provide their customers in key regions with an essential portfolio of renewable and recycled attributed building blocks. These transparently attributed, ISCC Plus certified feedstocks enable players in a broad range of industries to create their own high-performing, more sustainable products at scale and improve their environmental impact. They are part of Covestro CQ (“circular intelligence”) materials representing an attributed share of at least 25 percent alternative, non-fossil raw materials.

With this, Covestro co-creates sustainable value and a competitive edge by meeting the increasingly pressing needs from consumers, governments and investors toward climate neutrality and material circularity.

Increasing number of mass balanced products

Covestro has been offering an increasing range of mass balanced products for a broad number of applications. Be it high-performance polycarbonate plastics, be it components for foams, coatings, adhesives, films, thermoplastic polyurethane and many other materials – the customers will find a lot of opportunities for effort-less switching from fossil feedstock to alternative feedstock.

Covestro can process mass balanced feedstocks across the globe in existing manufacturing systems. For this, the company continues to enter partnerships with specialized suppliers, most recently with Encina, Neste and Borealis.

Create your own high-performing, more sustainable products at scale

…helping you and your customers to reach scope 3 targets & ESG goals!

Move ahead of competition by acting now

…and secure your access to more sustainable solutions and future partnerships!